|

|

| |

|

NV4500 5th GEAR FAILURES AND SOLUTIONS |

|

|

|

|

|

|

|

|

|

Why Stock and Full Spline NV4500

Mainshafts Fail

A Dan the Gear Man Tech Article |

|

Owners of diesel trucks equipped with NV4500 5

speed transmissions having been looking for a cure for 5th gear

failures from as early as 1993. The problem has been

experienced with both General Motors trucks using the 6.5l V8

Diesel and Dodge trucks with the 5.9l inline 6 cylinder Cummins

Diesel engine. So, exactly what is the problem and what is

being done about it?

“I Lost 5th

Gear!”

Almost all cases of mainshaft fifth gear failure

can be directly attributed to insufficient support for 5th

gear. In the classic case, the nut retaining the mainshaft

fifth gear backs off allowing the gear to slide back in the

transmission extension housing and out of contact with

countershaft 5th gear. This failure usually occurs without

warning or noise. You are driving happily along in 5th gear,

either you (or your cruise control) lets off on the accelerator

for a moment. You step on the accelerator to resume speed and

the engine races, but your transmission is no longer

transmitting power! White faced and shocked, you mutter “what

the #%!!” as you check to make sure the shifter is still in

fifth, then downshift to fourth and let the clutch out. Your

truck responds instantly as power is returned to the rear axle.

Your blood pressure lowers a bit and you try to upshift to 5th.

Again no power and no noise. You mutter “Oh no, I lost fifth

gear!” Back into fourth and away you go wondering if you are

going to make it home and HOW MUCH IS THIS GOING TO COST ME TO

FIX! |

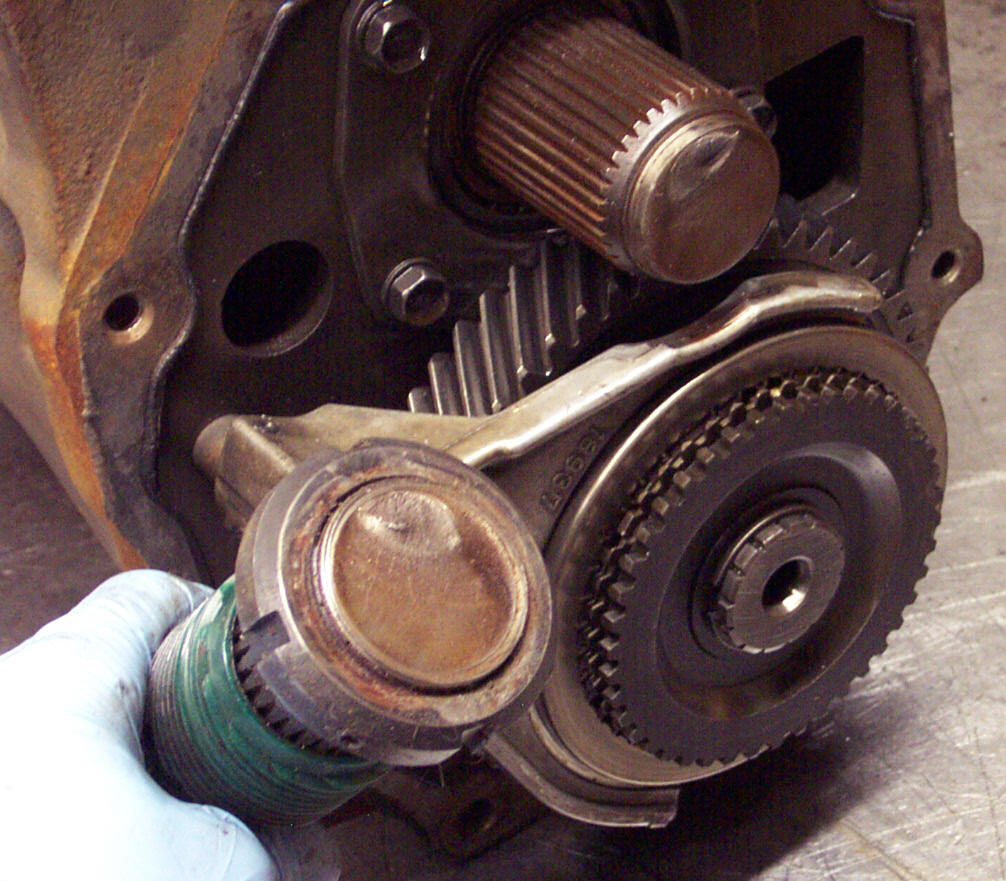

Typical 5th

gear failure on a stock NV4500HD transmission. Note the

reddish/orange sludge discoloring the shaft. This is a sign of

wear or “fretting”. What you see is actually oxidized metal

particles worn from the gear and shaft. Vibration and cyclic

loads are the main causes of fretting.

|

|

Every time someone tells me “I lost 5th gear”, I

am reminded of an occurrence in my youth. I was riding to

school on a Brockway school bus. We had a lady bus driver who

was a chronic gear grinder. One morning, when she was unable to

force the transmission into fifth gear, she radioed the school

that “I lost 5th Gear”.

The reply was something to the effect “Wh’ad

ya do drop it on the ground?”. I presume she had little

solace with that reply, but she bravely continued on in 4th gear

and we all eventually arrived at school. Like my bus driver,

you too will probably also make it to your destination after

your 4500 turns itself into a 4 speed because this type of

failure normally does not cause incapacitating damage in the

short term. Chances are, what occurred inside your transmission

was simply the 5th gear wore into the mainshaft. Once the gear

is loose, it will work the nut off until the gear slides back

and your day is ruined.

Nut Woes: Band-Aid Approach

to A Serious Problem

The initial attempts to prevent 5th gear failures

focused on the retaining nut which was a flat nut without a

lockwasher in the original configuration. New Venture first

added a lip on the nut that could be crimped into a keyslot,

then a concave spring lockwasher, and lastly a split nut with a

crossbolt to increase the thread contact. The aftermarket

weighed in with at least two styles of nuts with set screws.

Several chemical thread locking compounds have also been tried.

None of these “fixes” were successful in keeping the gear on the

shaft. They failed because they address a consequence of the

failure instead of the cause. (To find out the reasons why,

read on.) |

Clockwise from top left: flat nut, concave

washer, crimp lock nut, crossbolt lock nut, aftermarket nut with

2 setscrews, aftermarket nut with 3 set screws and brass pads.

|

|

Overloading

Aggravates Problem

Before discussing the problems associated with

factory partial spline and aftermarket full spline mainshaft

designs, I want to point out that they are good quality parts

made by reputable manufacturers. The 5th gear failings they

have are not metallurgy or workmanship related. Shaft wear and

gear failure is primarily due to design, but diesel engine

harmonics, and overloading also are significant factors. Owners

of diesel powered NV4500 equipped trucks often greatly exceed

the recommended horsepower and load ratings for their vehicle.

We have seen these trucks with engines putting out over 500

horsepower and 1,000 ft-lbs. of torque. We have also seen

combined truck and trailer weights exceeding 40,000 lbs.. Now,

when you consider the NV4500 is rated for up to 460 ft-lbs. of

torque and 19,000 lbs. combined truck and trailer weight, you

can see why part of the responsibility for transmission problems

must rest on the shoulders of truck owners who grossly exceed

the vehicle design limits and insist on making their

¾ or 1 ton

work like a 2 or 3 ton truck |

|

Mainshaft Types

and Weak Points

To support the 5th gear, the factory mainshaft

has both a splined area to transmit torque and a smooth machined

surface for the fully internal splined gear to press onto. The

end of the mainshaft is drilled and tapped for a pull rod so the

gear may be pressed on the shaft without damaging other

components inside the transmission. With this type of shaft,

only the tips of the gear splines are in contact with machined

support surface of the shaft. This area is also directly under

the gear teeth. Over time, the gear splines will actually wear

into the shaft. As this wear continues, the fit between the

gear and shaft becomes progressively looser. At this point,

every time you accelerate or decelerate in fifth gear, the gear

moves back and forth between drive and coast. This back and

forth motion against the nut is what eventfully causes the nut

to back off. Since the mainshaft bearing is inboard of the

gear, the transmission will usually operate in all other

speeds. |

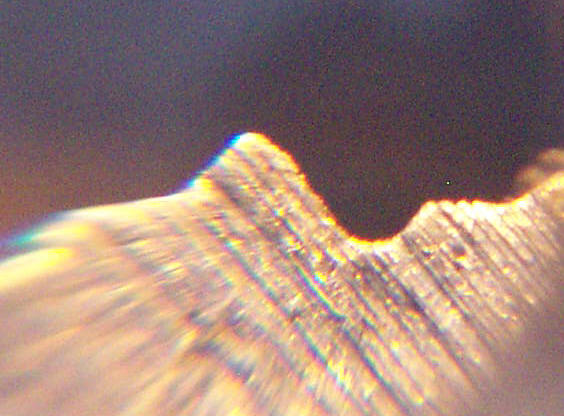

Stock New Venture mainshafts from Dodge NV4500HD

transmissions.

The top shaft had the typical fifth gear

failure. The splines are worn and you can see the wear marks in

the support surface to the right of the splines.

The lower shaft is a new takeout in perfect

condition. Note, the support surface is smooth |

|

The aftermarket introduced two types of imported

mainshafts with near full length splines in an attempt to remedy

the problems experienced with the factory shafts. The splines

on these shafts are considered “flexible” in the sense the gear

is not supported by pilot rings at either end so it can “flex”,

or rock under load. Both styles are used with the same fifth

gear design as original equipment. These shaft are most often

sold with an aftermarket mainshaft nut that has two setscrews.

First on the market was a shaft with splines

that were made to provide a fairly light interference or press

fit with the gear splines. This shaft design was introduced by

Blumenthal Manufacturing of Oklahoma City. Next on the market

was a shaft made for gear wholesaler Midwest Transmission of

Zumbrota, MN. With this design, the shaft splines are near full

length, but machined to be a slip fit with the gear. This shaft

is grooved to allow a 3 piece thrust washer to be inserted

between the gear and retaining nut. Both of these shaft designs

received tremendous positive press coverage as permanent cures

for 5th gear failures and were enthusiastically sold by almost

everyone in the transmission repair business including us.

Unfortunately, great confidence in these designs has not proven

to be fully justified. While the percentage of 5th gear and

related failures is probably lower with either full spline shaft

design in comparison to the factory shafts, the cold truth is

full spline shaft failures are occurring.

With the press fit type full spline shaft, gear

failures are identical to the original equipment shaft. In

other words, the gear loosens up on the shaft and eventfully

works the nut off the threads. To have any chance of keeping

fifth gear in place, the press fit between the shaft splines and

gear splines with this type of shaft must be quite tight. We

rejected nearly 50% of the shafts we bought of this design

because they did not provide a tight enough fit with the gear.

Long before we ever even heard of any failures with this type of

shaft, I discussed the importance of accurate machining with the

importer and the need to increase the spline contact to prevent

the same types of problems we had with the factory shafts. |

|

Full Spline Shaft with Light

Press Fit Splines

|

|

The other full spline shaft

utilizes a thrust washer between the gear and nut. With this

design, I know of no instances were the nut backed off. On the

downside, this shaft was designed so the 5th gear will easily

slip onto the shaft. This slip fit means the gear and shaft

splines may eventfully wear themselves away, at which point you

could “lose” fifth even though the nut is still in place. This

is a very noisy failure as the spline nubs jump over each other,

plus all the worn away spline material contaminates your oil.

There is one other major issue with this shaft. A secondary

function of the fifth gear is to keep the mainshaft rear bearing

tight against a thrust washer. With this shaft design, the

loose fitting gear cannot hold the bearing tight. If this

bearing is not held tight, it tends to wear into the shaft and

thrust washer which increases end-play. Excessive end-play can

lead to shifting problems, shaft misalignment, and catastrophic

failure. This style of shaft is somewhat weaker than other

designs due to the reduced shaft diameter at the thrust washer

groove. Breakage is not common, but it does occasionally snap in

high load situations. Despite the potential shortcomings, this shaft design

is very popular with both professional rebuilders and shade tree

mechanics because assembly is fast and easy without any press

tools. |

Full Spline Shaft grooved for thrust washer. |

|

The

Surprise

Culprit Is…..

The 5th gear splines used on all NV4500

transmissions are of side fit, involute configuration. Involute

splines are self-centering, have curved sides, and offer greater

torque-transmitting capacity than any other type. Side fit

means only a portion of the flanks of each spline are in contact

with the mating spline and it is this characteristic that is

culprit #1 in the Case of the Lost 5th Gear.

Side fit, involute splines

are widely used and well proven for transmitting

inline torque. Common examples include input shafts,

output shafts, synchronizer hubs, transfer case chain sprockets,

propeller shaft slip yokes, pinion yokes, and axle shafts. This

spline style is not often used to transmit torque in

applications were the torque input is from the side as is the

case of the NV4500 mainshaft fifth gear, unless there is some

type of additional support (such as pilot rings) to prevent the

gear from rocking on the shaft. None of the previously

discussed mainshafts use any type of ring or pilot to prevent

axial movements occurring under load although the factory gear

does derive some weak support from the unsplined portion of the

shaft. |

If you take a magnifying glass and view a cross

section of a 5th gear pressed on the mainshaft splines, you will

clearly see the no-contact areas between the tips of each spline

and the root of the matching spline. You can also see how short

the contact surface is between mating splines. The 5th gear to

mainshaft contact area of the mating splines is

less than .040” high.

The unsupported, no-contact areas or voids, are greater than

1/2 the distance from

the minor diameter of the shaft to the major diameter of the

gear. With both the factory and full spline shafts these

unsupported areas are where wear and eventual failure begin.

Such movement will be minute at first, but over time it will

increase as the matching parts wear. To eliminate movement, we

must have effective and rigid support for the 5th gear. To do

this we need to change the design of the shaft, gear, and

retaining nut. |

|

Now, lets turn our attention

back to the much maligned factory mainshaft with it’s partial

5th gear spline. These shafts have a spline length of just

under ¾”.

In addition, for additional gear support there is a smooth

machined surface just over 1” long. For manufacturing reasons,

there are also reduced diameter areas between the splines and

support surface and between these two features and adjacent

portions of the shaft. The matching gear (which is also used on

both full spline shafts) is 2.25” long with internal splines cut

the length of the gear. The gear splines are beveled at each

end.

Many people assume New

Venture choose partial splines over full splines because it was

cheaper. The fact is it is more expensive to make a partial

spline shaft. Why? The splines are rolled before the shaft is

hardened. After the

shaft is heat treated to harden it, the support surface is

ground to a very, very precise dimension. New Venture could

have saved money by rolling full length splines in the first

place. So why didn’t they? Well, I can’t be sure, but a

comment made to me by a New Venture engineer about the

importance of keeping 5th gear concentric on the shaft had to be

a consideration. New Venture tried to use the gear splines

pressed onto a smooth support surface instead of pilot rings.

This approach is reasonably effective with gas engines and

moderate loads. However, with diesels, the engine harmonics and

horsepower in heavy duty applications creates loads beyond what

this design can handle without wear given the shaft size. With

a factory mainshaft and gear, you typically “lose” 5th gear when

the gear splines have worn into the shaft to the point where

repeated axial gear movement works the nut free. New Venture

tried to fix the problem by addressing the consequence (by

changing the nut design) of the gear working loose, instead of

the cause (insufficient gear support). End result: A big

problem and a bad reputation for an otherwise excellent

transmission. |

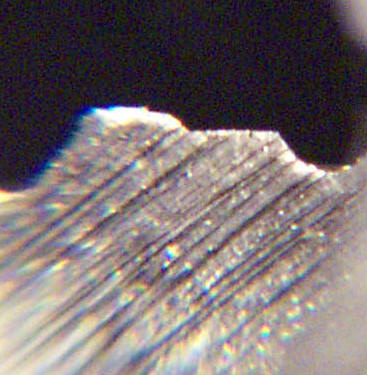

Cross-section view of 5th gear pressed over

unsplined portion of factory shaft.

Look through magnifying

glass and note how splines have already slightly indented shaft

when pressed on.

|

|

Now, let’s take a look at

the press fit, full spline shaft. The theory here is longer

splines are better, but the side contact, “flexible” spline with

it’s limited spline to spline contact and large unsupported

areas makes this design subject to the same types of failure as

experienced with the factory mainshaft. Some support can be

derived by having a very tight fit between the gear and shaft.

However, with the “average” fit, premature failure is a distinct

possibility.

The concept of the thrust

washer style full spline shaft is simple. The design assumes

the gear is going to come loose anyway, so they grooved the

shaft to accept a split thrust washer between the gear and nut.

With this design the thrust washer will probably keep the nut

on. The problem here is the designers concentrated on

preventing the nut from backing off and ease of assembly. In

this they were successful, however, by making the shaft so fifth

gear and the rear bearing would be a slip fit, wear and fretting

is almost guaranteed. Result: potential for reduced service

life. |

|

Spline Cross Sections

Showing Progressive Wear.

(top right) New, unworn involute

splines. Note the sides of the teeth are slightly curved. Also

note the tips are slightly concave from being roll formed.

(bottom left) Typical wear found on a

factory shaft or press fit full spline shaft after the second

failure when a gear was just reinstalled to temporarily return

the transmission to service. Note the spline is worn almost to a

knife edge.

(bottom right) Worn off splines typical

of thrust washer type full spline shafts when the gear jumps the

splines. The matching gear splines are similarly worn. |

|

|

|

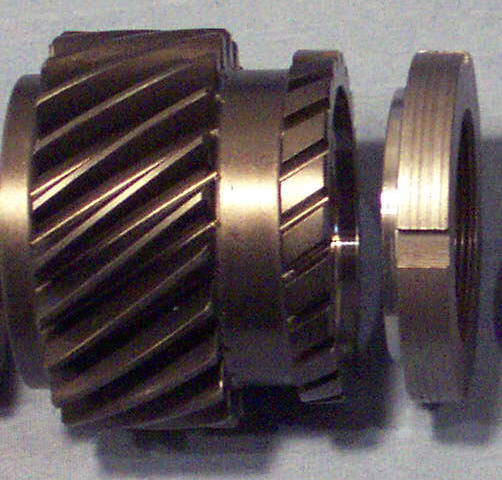

Close-up of groove and thrust washer style, full

spline mainshaft. One split washer is removed to show detail.

Thrust Washer Style Mainshaft broken off at

Thrust Washer Groove

|

|

Comparison to

Ford ZF42 and ZF47

So far, we have only talked about the NV4500 in

GM and Dodge vehicles. How did they stack up against the

contemporary Ford ZF42 and ZF47 5 speeds? These transmissions

have many durability issues, but “loosing” fifth gear isn’t one

of the common ones. Unlike the 4500 with its fixed mainshaft

gear and bearing supported countershaft gear, the ZF’s used an

extremely tight, press fit between the gear and countershaft

with no splines or keys. On the mainshaft, the gear is

supported by a two piece bearing. The rear output bearing is

outboard of the gear. The bearing is held in place by a snap

ring on 4x4 models or the rear output yoke on 4x2 trucks. Since

the bearing is outboard of the gear, lateral gear movement is

limited. To be sure, most of the Ford Diesels coupled to these

transmissions were rather anemic compared to the Cummins, but

the fact is the basic 5th gear design was more trouble free than

the NV4500.

What Next?

So, you ask “Is there any solution to this #&*!

problem besides a different truck and/or transmission?” Well,

yes there is. The answer is pretty simple (increase gear

support), but it required redesigning the mainshaft, gear, and

retention system.

The Challenge

The root cause of NV4500 mainshaft fifth gear

failures is simply insufficient support for the fifth gear under

real world conditions. The solution is also simple, increase

support. To provide a practical and customer installable design

at a reasonable cost was the challenge. We also wanted to offer

the improved design for all NV4500 transmissions including GM

and Dodge light duty models.

New Design

Features

First off, we knew we had to use a partial, fixed spline shaft

to eliminate the rocking motion of the gear that plagues all

previous mainshaft designs. The unsplined area is

increased in diameter to a size larger than the shaft splines.

This gear design was modified from a full spline to a partial

spline. The area without splines is precision machined to

provide an “interference” or press fit with the larger diameter,

unsplined area on the mainshaft. Depending upon

application, the gear may be shorter or longer than stock.

The rear gear face for most applications is modified to

accept a pilot ring. The rear single lock nut is replaced

by either a double or triple nut retaining system. The

outer nut is a lock nut. The inner nut may be flat or

incorporate a pilot ring depending upon application. On new

shafts, a hardened, tanged thrust washer is also used. For

retrofit kits, a Belleville spring lock washer is used. We

also had to invent several new tools to ease installation.

To increase holding power and decrease the chance of vibration

induced fretting, we use several Permatex® locking

compounds with 3,000-4,000 psi. shear strengths. Our

Patented design is known as the

Torque King®.

|

|

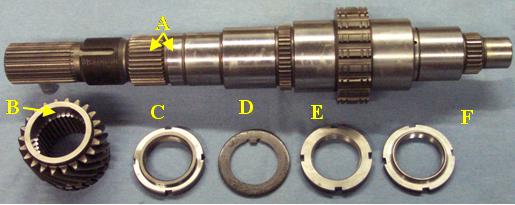

The

Patented

Torque King®

eliminates NV4500 5th gear failures!

A.

Longer Splines

(left arrow)

Shaft Pilot

(right

arrow)

B. Counterbore under gear teeth (fits A)

C. Inner nut with machined pilot ring

D. Hardened Anti-Rotation Washer

E. Center Nut

F. Outer nut with lip to stake in key slot |

|

Benefits of the

Torque King®

What’s all this mean to you? Dependability and

reliable performance unmatched by any other NV4500 mainshaft/gear

design. With the

Torque King®

design, the splines have one function and one function only; to

transmit torque from the gear to the mainshaft. The gear is

supported and kept concentric on the mainshaft, by press fits

between the smooth gear bores and supporting rings. With this

design, the troublesome axial movements and wear that cause

factory and full spline shaft failures are eliminated. Under

identical service conditions, a transmission with the

Torque King® will

provide longer and more trouble free service than any factory or

full spline mainshaft. Less downtime and longer life make the

the

Torque King®the

most cost effective way to keep your NV4500 equipped

truck in service. Whether you rely on your truck for commuting,

work, or touring, you can put your mind at ease about 5th gear

failures with the

Torque King® the

mainshaft and fifth gear system designed and built to last. |

|

With

Torque King®

matched shaft and gears sets, the splines have only one

function: transmit torque. The gear is rigidly supported by

pilots. Close-up of Inner Nut shows how pilot ring is machined

as part of the hardened inner nut. This ring fits a very

accurately machined, matching counterbore in the rear of the

gear.

Torque King®

gears

for

most Dodge applications use fixed splines with a long pilot ring

under the gear teeth and a short pilot on the nut as shown

here. GM applications are piloted under the gear teeth only due

to design differences on GM NV4500 transmissions.

Dan The Gear Man Tech Note: When I retired from the day to day operations of the business and turned over the reins to the younger family members, it was with the understanding I would not override their decisions. When the time came to renew the long term production contract for our Torque King® Mainshaft Sets, the family looked at the advancing age of NV4500 equipped vehicles, plus the unavailability of original equipment or better 3rd, 4th, and countershaft gearing. After deliberation, the decision was made to let the contract lapse even though Torque King® sales reached a record high in 2011. My arguments that Cummins powered trucks with NV4500 transmissions are going to stay on the road for many years did not carry the day. So as of January 2012, we sold out on Torque King® mainshaft Sets and Master Overhaul Kits for New Venture NV4500 transmissions. There are no plans at this time to resume production. |

|

Torque King®

In Vehicle Retrofit Kits

Have an otherwise

serviceable NV4500 that just suffered it’s

first fifth gear

failure? Return your transmission to service without removing

it from the vehicle with the

Torque King® Retrofit

Kit. This unique kit consists of a precision machined

steel sleeve that is installed over the worn support surface of

your factory mainshaft, a

Torque King®

press fit gear, double nut package with lockwasher, rear output

seal, special tools, several Permatex® products and required

tools. The

Torque King®

Retrofit Kit is the only “fix” on the market that restores the

critical press fit between the gear and shaft. Plus, this

innovative new kit provides steel support rings for both sides

of the gear. The splines are only used to transmit torque.

Permatex® Bearing Mount is used to restore the fit of the worn

mainshaft splines. This Kit is only recommended for use on a

transmission that 5th gear has either not failed or just failed

for the FIRST time! |

Torque King®

Retrofit Kit for NV4500 Transmissions

(Early NV4500HD Kit shown here) |

|

When NOT to Use

the

Torque King®

Retrofit Kit

If your NV4500 with a factory mainshaft

was returned to service after

the first 5th gear failure with any combination of

factory gear, nut, bearing lock, welding, etc., it will have

severely worn splines and excessive bearing end-play. These

types of temporary repairs MURDER your transmission and we

absolutely do not recommend

using our Retrofit Kit under these circumstances as your

transmission is in desperate need of a total rebuild. In fact,

we won’t even sell you a Retrofit Kit if we know this!

If you have a high mileage transmission with

150,000 miles or more, we recommend you have it rebuilt instead

of installing the Retrofit Kit. High mileage transmissions

usually have excessive end-play which is a good indication the

useful service life of the bearings is about over.

The

Torque King®

Retrofit Kit is only compatible with genuine New Venture

original equipment mainshafts. It will not work with any

aftermarket shaft of either full or partial spline design! |

|

REFERENCES

An excellent reference for

mechanical design and manufacturing is the

Machinery’s Handbook

published by Industrial Press, 200 Madison Ave., New York, NY

10016. Phone: 1-888-528-7852. We derived much of the

information we used in identifying the reasons for fifth gear

failures and in the invention of the

Torque King® from

this source.

Instruction Sheet K6855309 from

the Chrysler Motors Mopar Parts Division dated 7/1/98 and revised

9/23/98 details the service procedure for the clamp mainshaft

nut in “repairing” fifth gear. The following statement

appears: “Caution:

if fifth gear nut has backed-off in operation, then fifth gear

replacement is also required with fifth gear nut.”. No

mention was made about mainshaft wear or the chances this “fix”

would hold up when installed on a worn out shaft.

Two interesting back-to-back

articles appeared in the Turbo

Diesel Register on this subject in issues 30 (pg.36) and

31 (pg. 23). These articles were major factors in

acceptance of

the thrust washer design, full spline shaft as the end-all cure

for 5th gear failures. The full spline shaft sold by Standard

Transmission Transmission and Gear Company of Texas was a major

topic of both articles. We purchased one of these shafts from

Standard Transmission in 2002 which is identical to the shaft

imported by Midwest Transmission. The shortcomings of the

thrust washer design full spline shaft that we detailed in our

discussion above were not readily apparent when these articles

were written. For reprints, Contact

TDR at 770-886-8877.

Address: 1150 Samples Industrial Drive, Cumming, GA 30041. On

the web: turbodieselregister.com.

An article I wrote on

Catastrophic Manual Transmission Failures appeared in issue 44

of the Turbo Diesel Register

starting on page 142. To view a generic version of this

article, click here:

Causes of Manual Transmission Failures.

|

|